Revitalizing Legacy Systems: GP Plasma’s Expertise in Upgrades and Retrofits

In today’s fast-evolving industrial landscape, replacing aging equipment can seem like the only option—but there’s a smarter alternative. GP Plasma specializes in transforming hard coating systems, metallizers, and inline, batch, and roll-to-roll systems through expert upgrades and retrofits. By integrating the latest technology, we enhance performance, cut costs, and extend the lifespan of your existing equipment.

Affordable System Upgrades

Rejuvenating your old systems allows integration with modern data analytics and keeps them serviceable with modern spare parts for years to come.

Consider Robbjack, a California-based precision tooling company. Their outdated coating machines were holding them back until GP Plasma stepped in, retrofitting them into state-of-the-art systems that boosted efficiency and unlocked new potential. Across the country, Texas A&M University saw similar success when we modernized their research equipment, showcasing the versatility and impact of our tailored solutions.

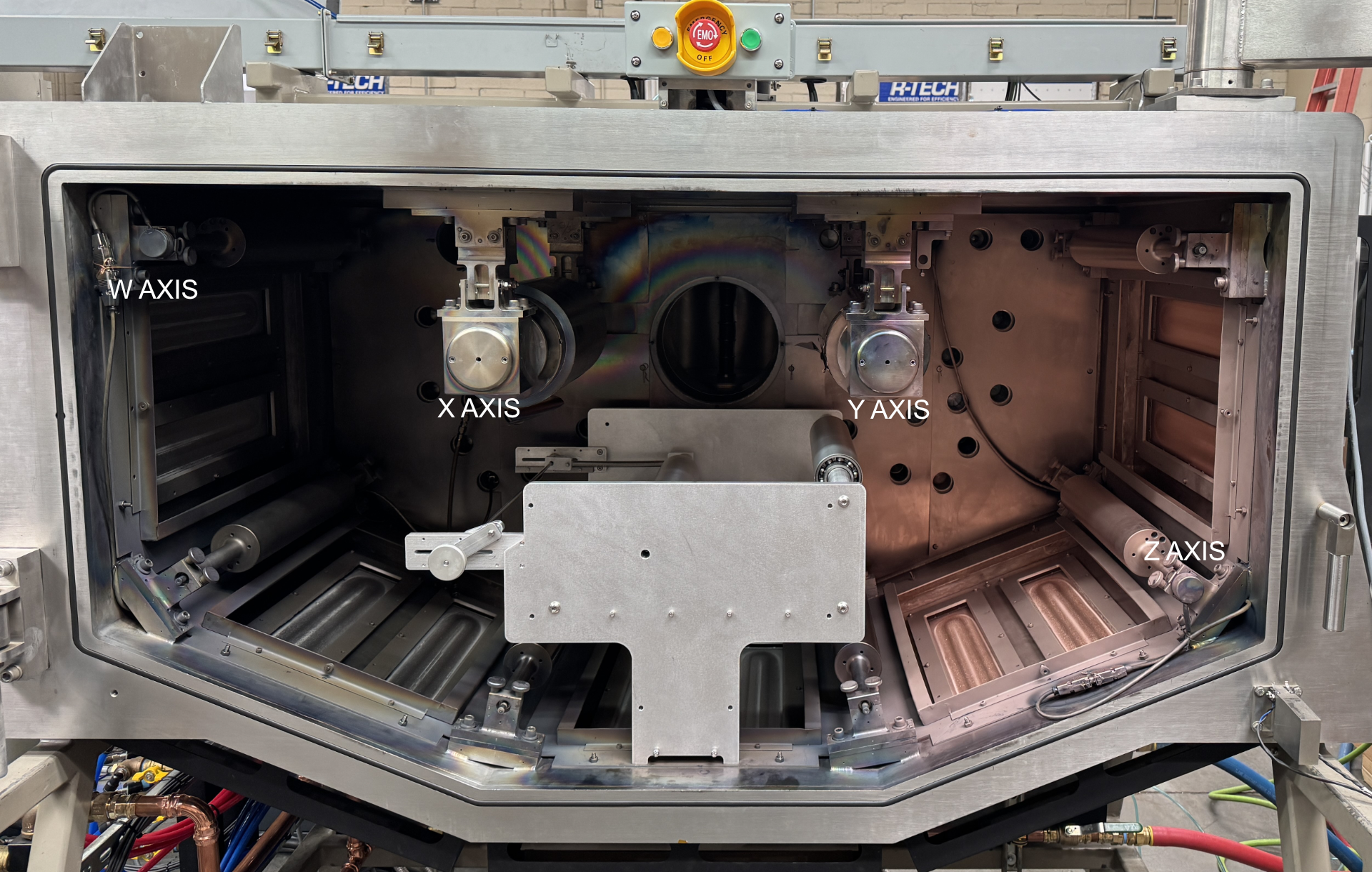

Below is an example of updating old controls equipment (DVD players now being obsolete) with modern interface hardware and modular control flexible system software.

These upgrades do more than just improve performance—they support sustainability by reducing waste and promoting equipment reuse, aligning with today’s push for greener industry practices. Discover more success stories and see how GP Plasma can revitalize your systems.

More on retrofits: https://gpplasma.com/blog/d-chamber-web-coater-retrofit

Texas A&M University

A full coating system rebuild to fit within a defined budget allowing for future upgradability.