The SC-1 Hybrid ALD System Offers Novel Development Opportunities

Swiss Cluster - Building the Next Generation in Thin Film Deposition Systems

GP Plasma is proud to support Swiss Cluster as their North American representative. Please contact us to discuss ALD and ALD hybrid solutions for your applications.

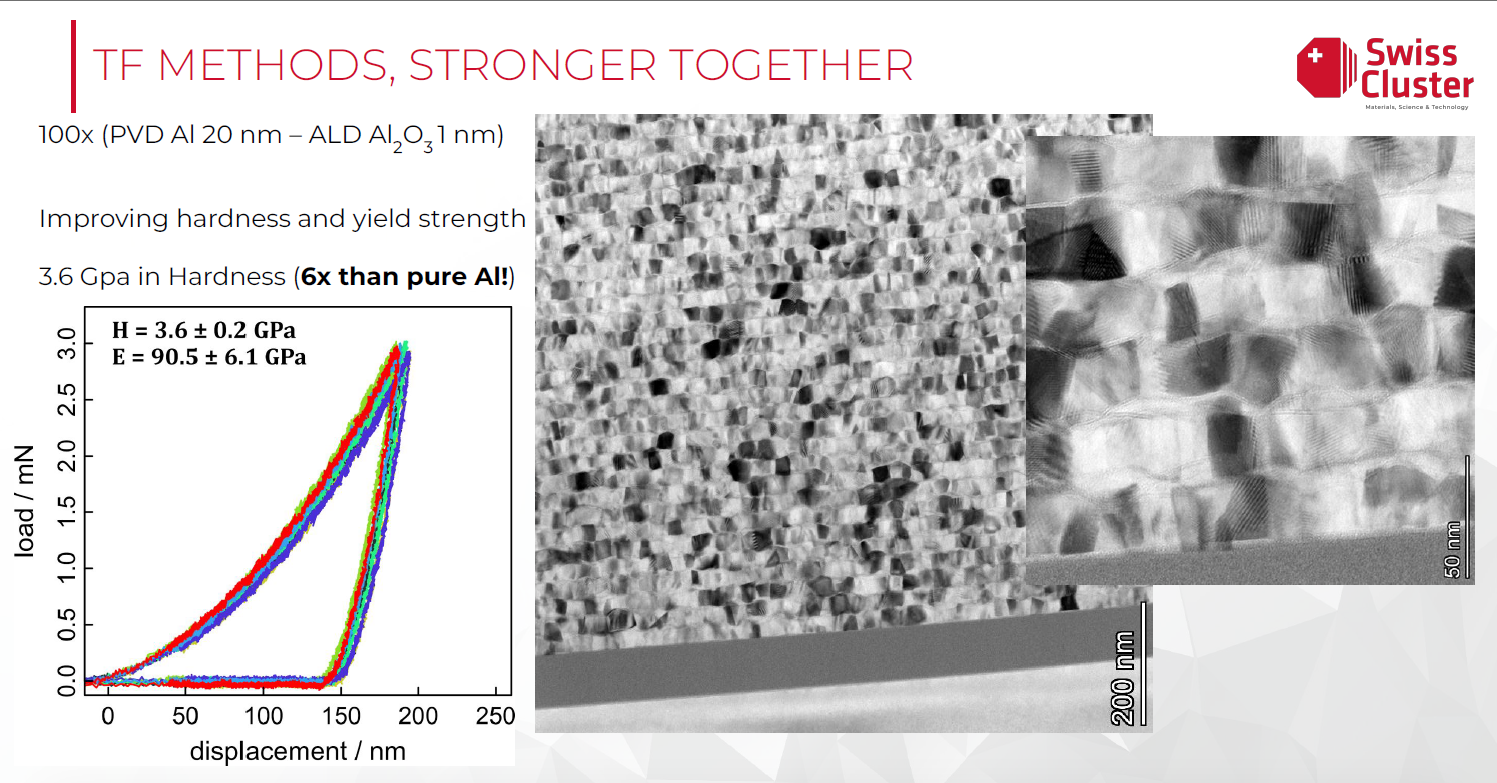

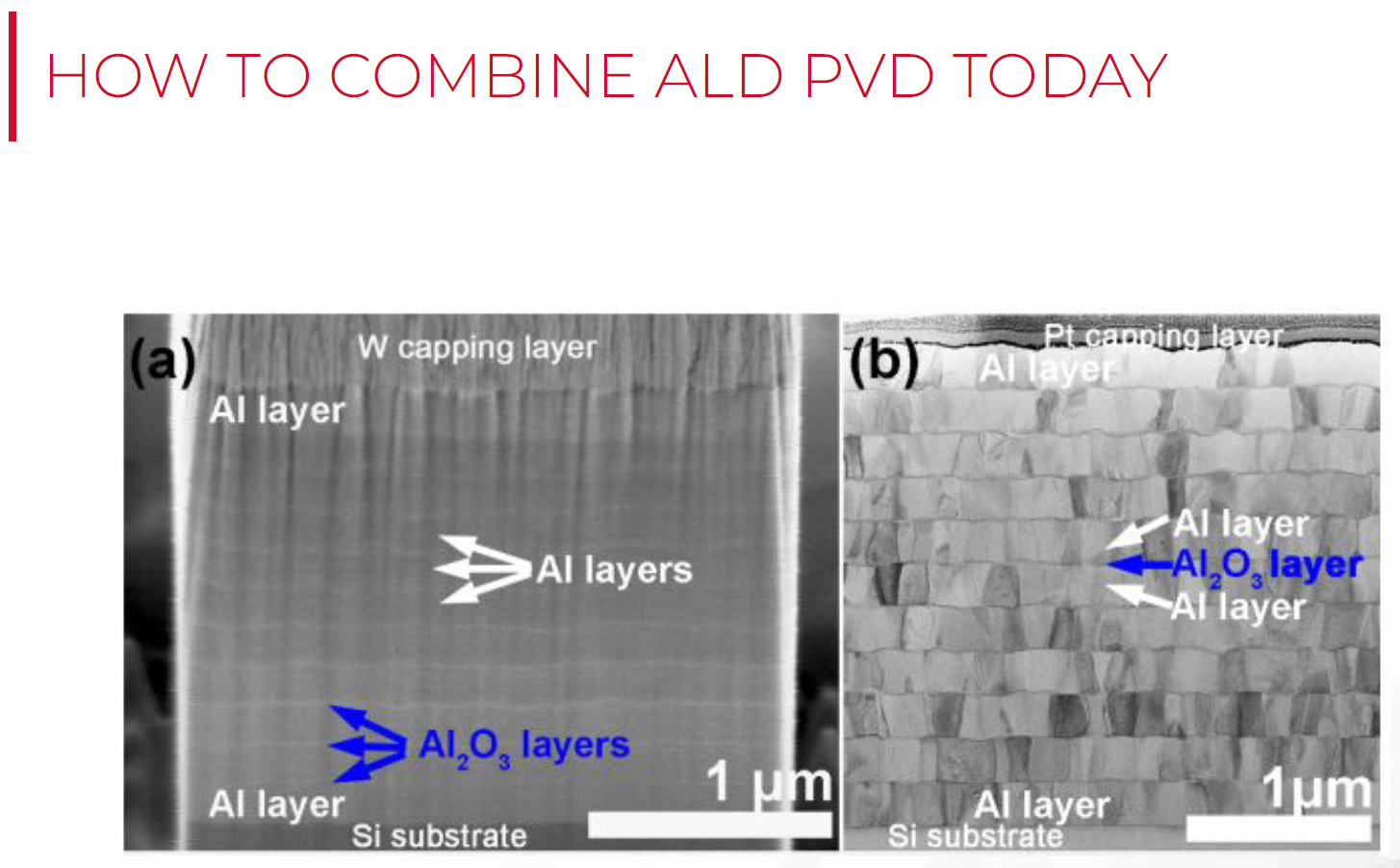

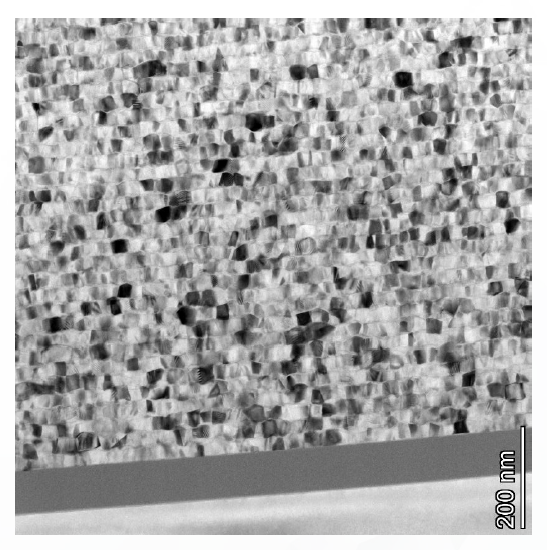

By combining hybrid processes of ALD and PVD and PECVD into the one system, a greater range of flexibility is possible allowing materials scientists to produce novel coatings architectures, structures and properties that arise from the different capabilities. With ALD having aspect ratios of up to 5000:1, the pin holes and voids around macroparticles found within other deposition techniques are easily filled for enhanced oxidation, barrier and diffusion layers. Even just a few nanometers of ALD can help change the structural growth of a following PVD layer, allowing novel layer stacks to be built.

The Series SC-1 Hybrid system is for leading groups in:

Semiconductor stack formation

High Temperature applications

Metamaterials

Batteries

Solar Cells (i.e., Perovskites)

Mechanics

Optics

Medical

We are really excited by the SC-1 hybrid coater for R&D, to develop novel materials and structures using ALD combined with PVD or PECVD deposition.

Series SC-1

Unique patented technology

(ALD/PVD integration in a single system)

ALD Reactor Type

• Single Wafer (Up to 800°C and Temperature gradient stage)

• MW PE-ALD

Lines

• Up to 12 gas lines with 10 individual inlets

• Non-heated lines

• Heated Bubbler (200 °C) lines

PVD Reactor Type

• Single Wafer (Fixed or Rotational and z-stage up to 800 °C)

• Up to 8 Magnetron Sputtering sources

• Up to 8 Evaporators

• Power supplies: DC, RF, HiPIMS, bias

Accessibility for multiple in-situ metrology tools

• ToF- MS

• OES

• In situ wafer stress measurements (by laser)

• In situ ellipsometer

• QCM

• Plasma diagnostic tools

PVD materials on the System

Sputtering (Metals, Nitrides)

Evaporation (Li, Na and Metal-Organics)

ALD materials on the System

Oxides (Al2O3, TiO2, ZnO, ZrO2, HfO2, LiOx)

Nitrides and Fluorides

Combination (LiPON, LiF,LiNb3O8)

Thermal and MW Plasma process

Ozone pre-treatments or as process gas

unique features:

Glovebox integration with direct access to ALD/PVD chambers.

Unique, patented, pioneering technology.

Combination ALD / PVD

Unmatched metrology capabilities

Find out more here: Series SC-1