Finding Scarce Material Performance Alternatives to Mitigate Supply Chain Risk and Lower Costs

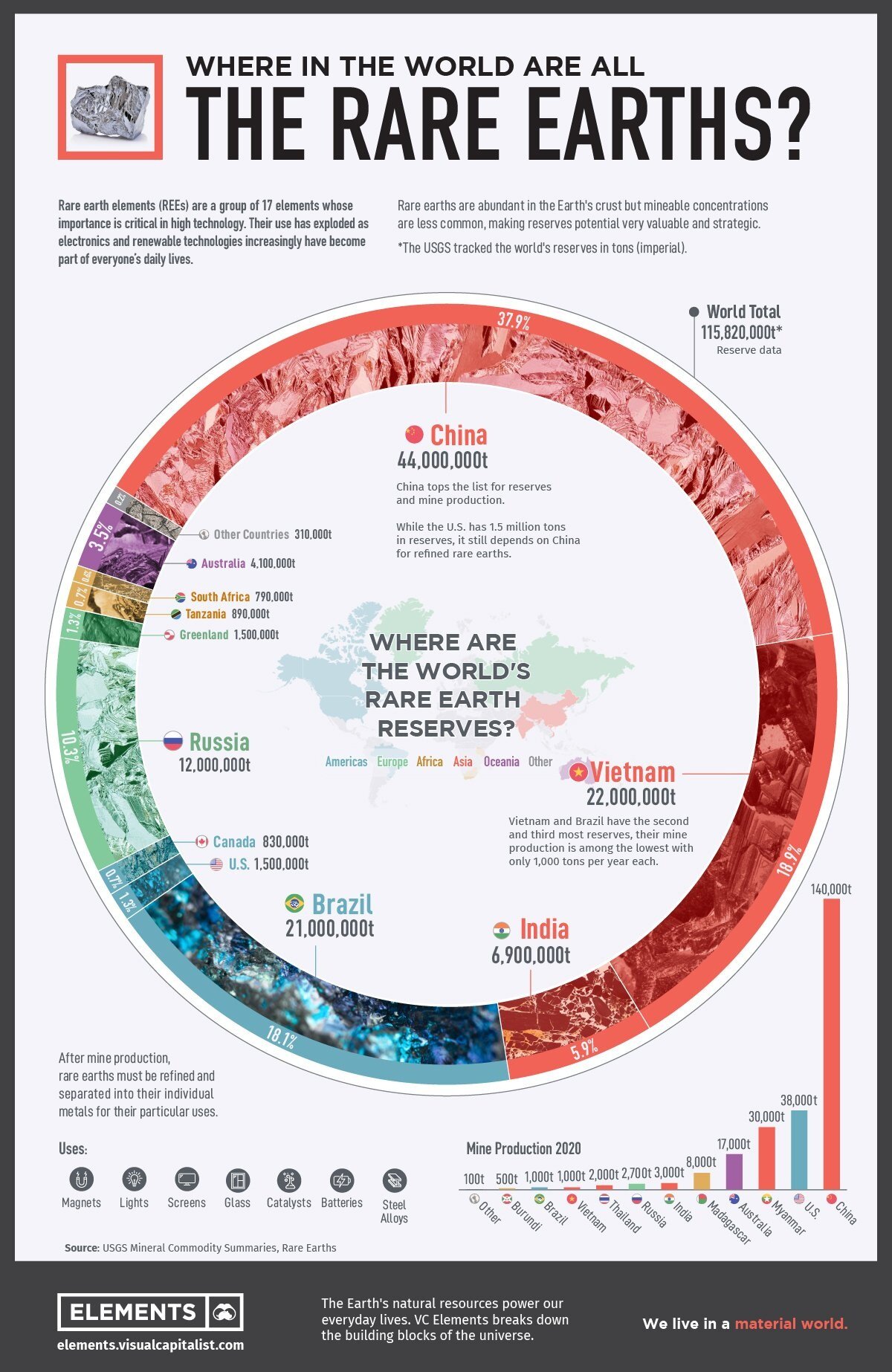

Mitigation of current and future supply chain disruption and finding low cost abundant alternatives for rare earth materials (and/or precious metals) is increasingly imperative.

Reuters: World battles to loosen China's grip on vital rare earths for clean energy transition

Zerohedge: The Battle For Rare Earths & Critical Minerals Heats Up

Reuters: Pentagon has strategic germanium stockpile but no gallium reserves

The post image above is from a 2021 article shared on the visual capitalist, covering what rare earths are, some application uses, where they come from and the supply chain.

A solution to efficiently find alternatives to these materials is needed for a wide range of technical products from chip manufacturing to batteries and solar cells to;

reduce supply chain dependence on Rare Earths.

reduce costly materials with cheaper more abundant ones without loss of performance

The project goal is to find material combinations to achieve similar properties to the rare earth element being replaced, a solution that can start with a performance requirement and work backward to the composition needed to achieve it.

But it is not limited to rare earth replacements, think reverse optimization for any material and performance parameter!

Replacing Iridium in Fuel Cell PEM’s?

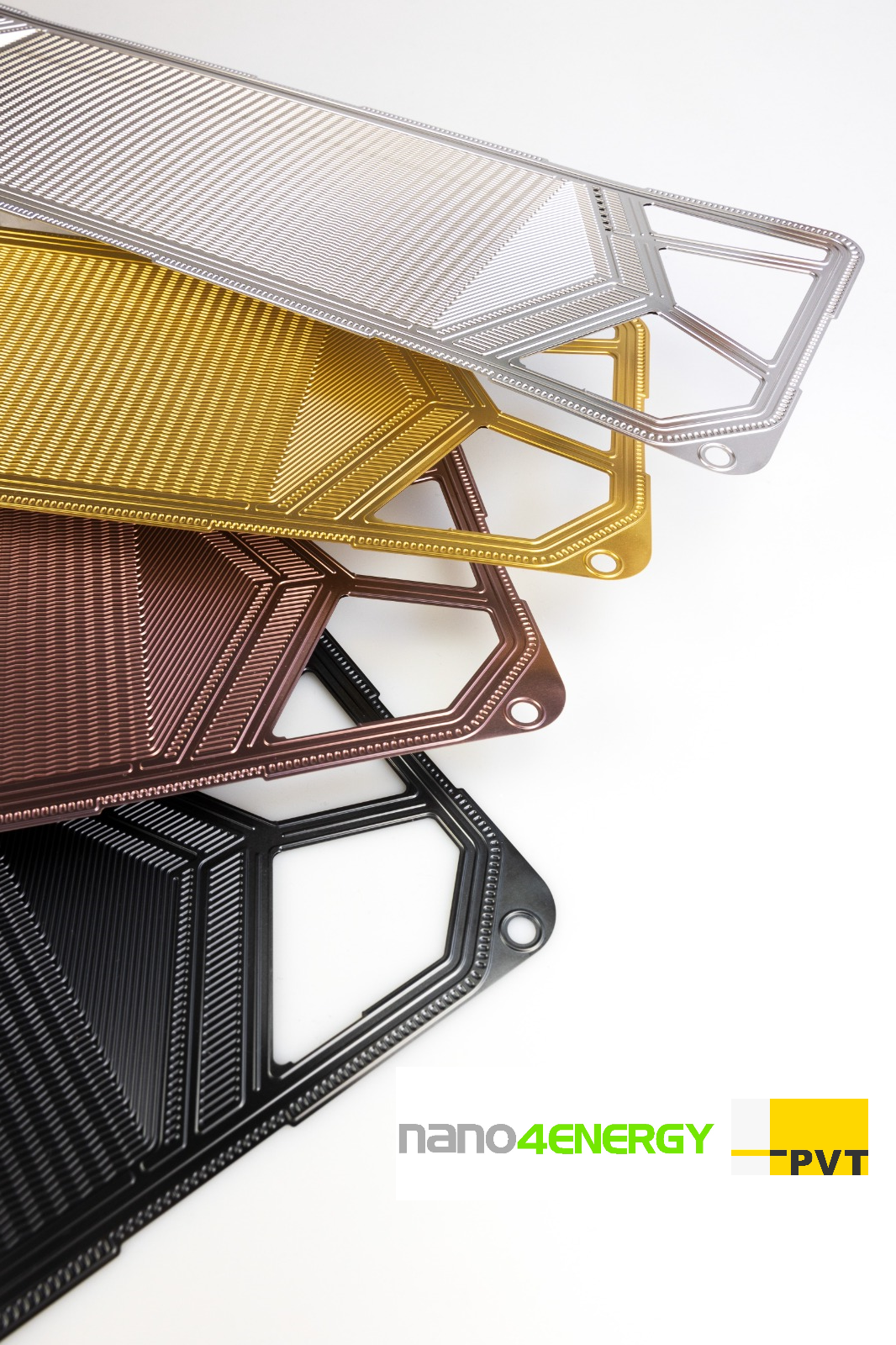

Not just the proton exchange membranes but even the bipolar plates can be reverse optimized to find the ideal material combinations for both longevity and performance will be invaluable.

“Bipolar plates should be electrically conductive, highly chemically resistant to the operating conditions, and highly thermally conductive for better heat transfer across the cell.”

from Sivakumar Pasupathi et. al. in Recent Advances in High-Temperature PEM Fuel Cells, 2016

Interestingly, the rare element Iridium [1] used in the proton exchange membranes is another candidate to reverse optimize for alternatives. “One of the worlds rarest metals, Iridium is an essential materials for the manufacture of proton exchange membranes (PEM)s used in water electrolyzers that produce Hydrogen”.

[1] https://fuelcellsworks.com/news/toshiba-announces-plans-to-forge-iridium-supply-network-for-clean-hydrogen-production/

Current State of art:

Molecular Dynamics (MD), Boundary Element (BE), Finite Element (FE) methods are all too computationally slow & costly.

In optimization processes or parameter identification tasks they rely on half empirical sensitivity analysis, but the errors become too high very quickly!

MD ~5% starting error (in dependence on what truncation or tight binding methods are applied),

FEM/Boundary Element ~3% starting error

These methods can’t achieve the precision needed and are not invertible for reverse optimization!

Join our Project Consortium

If you are interested in joining a project consortium to gain early access we are developing a demonstrator concept as a first phase:

FilmDoctor is the only tool that will have this capability. As any solution must have the world formula approach to extend the capability to arbitrary properties, which are attributes or degrees-of-freedom and these are just dimensions.

A fully reversible/invertible analytical physics model without loss of accuracy.

Computationally efficient.

Phase 1: Theoretical Demonstrator

Development of FilmDoctor techniques to demonstrate mechanical aspects up to 100 layers.

Show substitution of mechanical properties of rare earths.

Phase 2: Extend to the other properties of interest

Electrical, dielectric, optical etc.

Requires World Formula approach [1] where any other property can be calculated and optimized.

Design and optimize an example problem (consortium partner material) to replace the scarce materials.

Use plasma deposition system to produce low cost demonstrator material as a rare earth replacement.

Impact:

Accelerates product development timelines of nanomaterials for many potential materials applications such as chip manufacturing, solar, battery, hydrogen storage, energy efficient glazing etc.

Can be used by companies to get around blocking patents.

Can be used by companies to build a moat around existing patents.

Next Steps

Perhaps you can’t leverage it right now but you have colleagues that can. So, share the story!

Get in touch to discuss project partner responsibilities/duties and cost. Costs are dependent on participation in both phases, number of consortium partners, software user license's desired for the end product and what partners can contribute 'in-kind' to the project execution.

[1] N. Schwarzer, “Quantum Gravity War – How will the nearby unification of physics change the future of warfare”, Jenny Stanford Publishing, ISBN: 9789814968584