HIPIMS

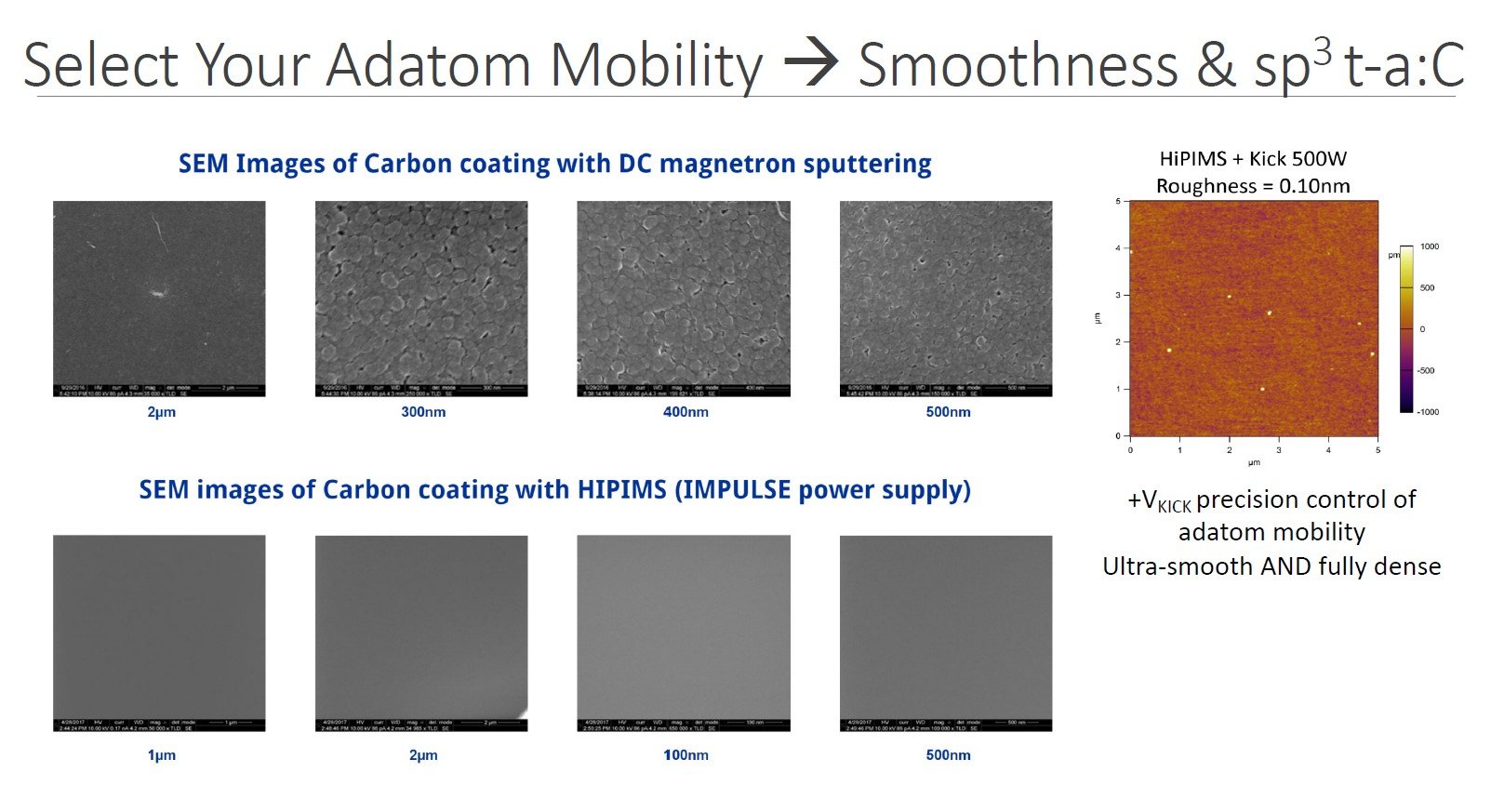

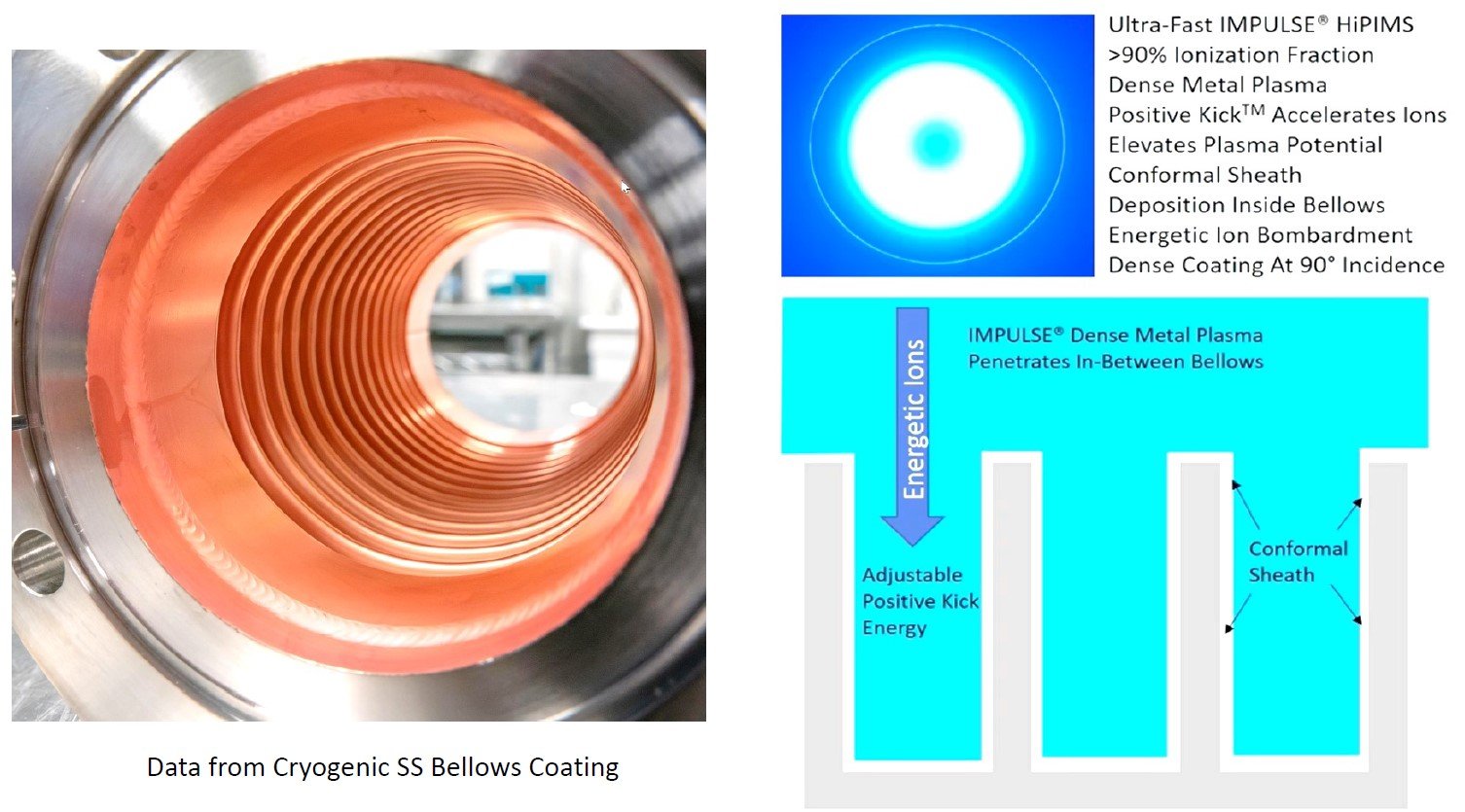

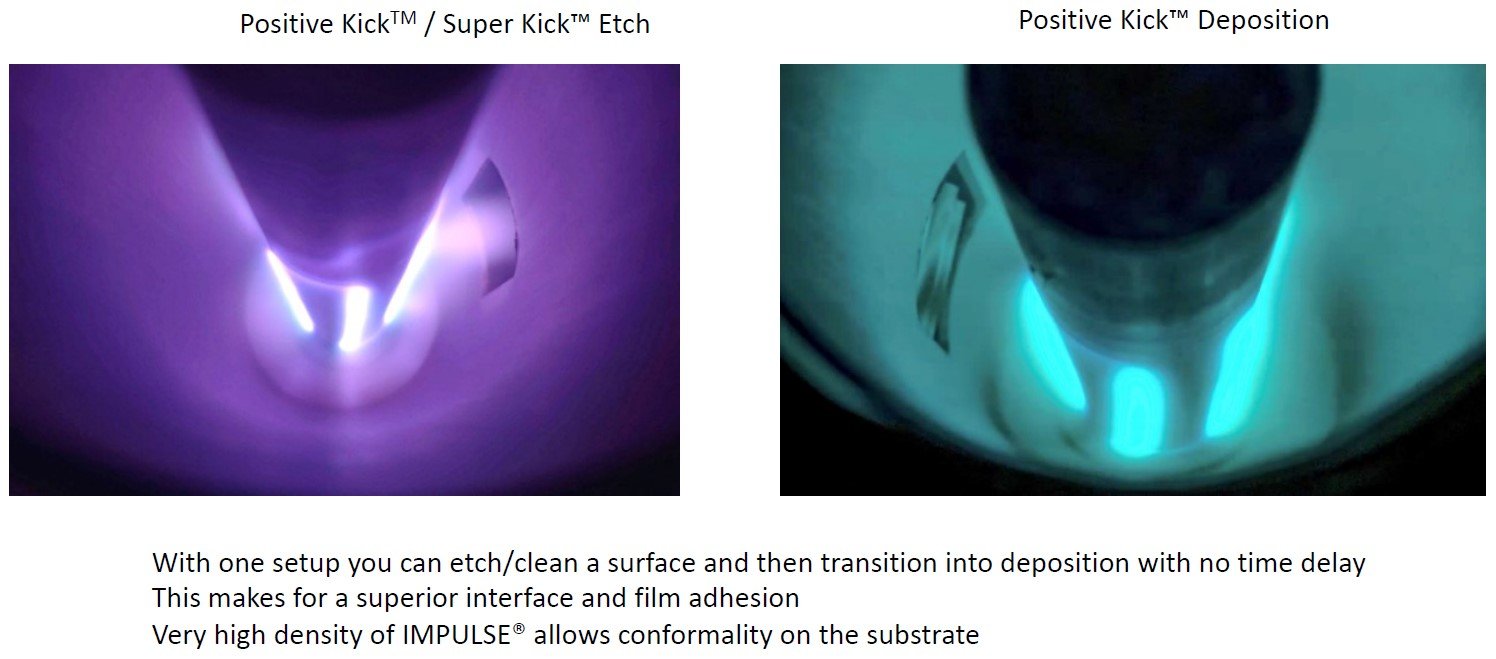

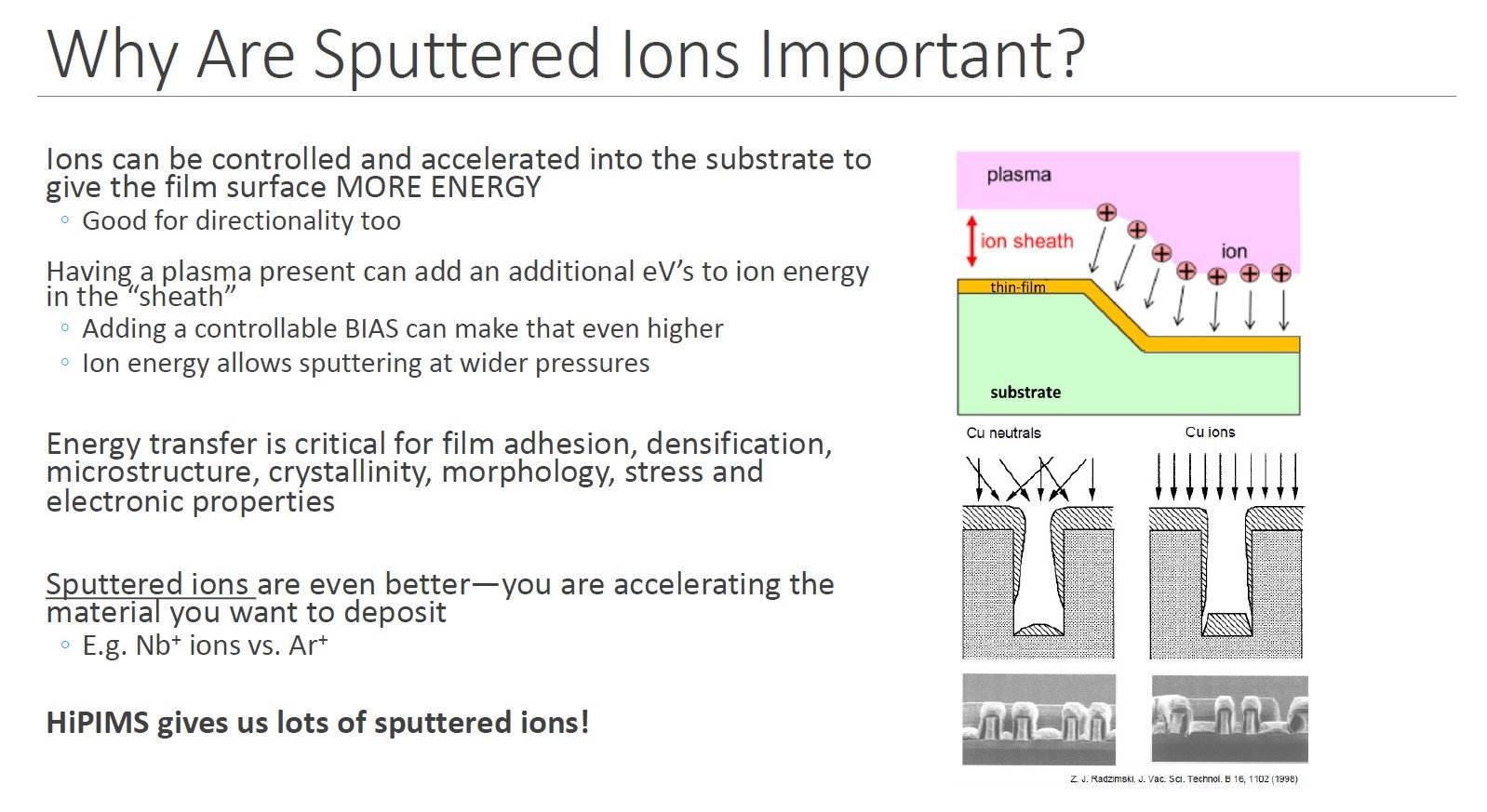

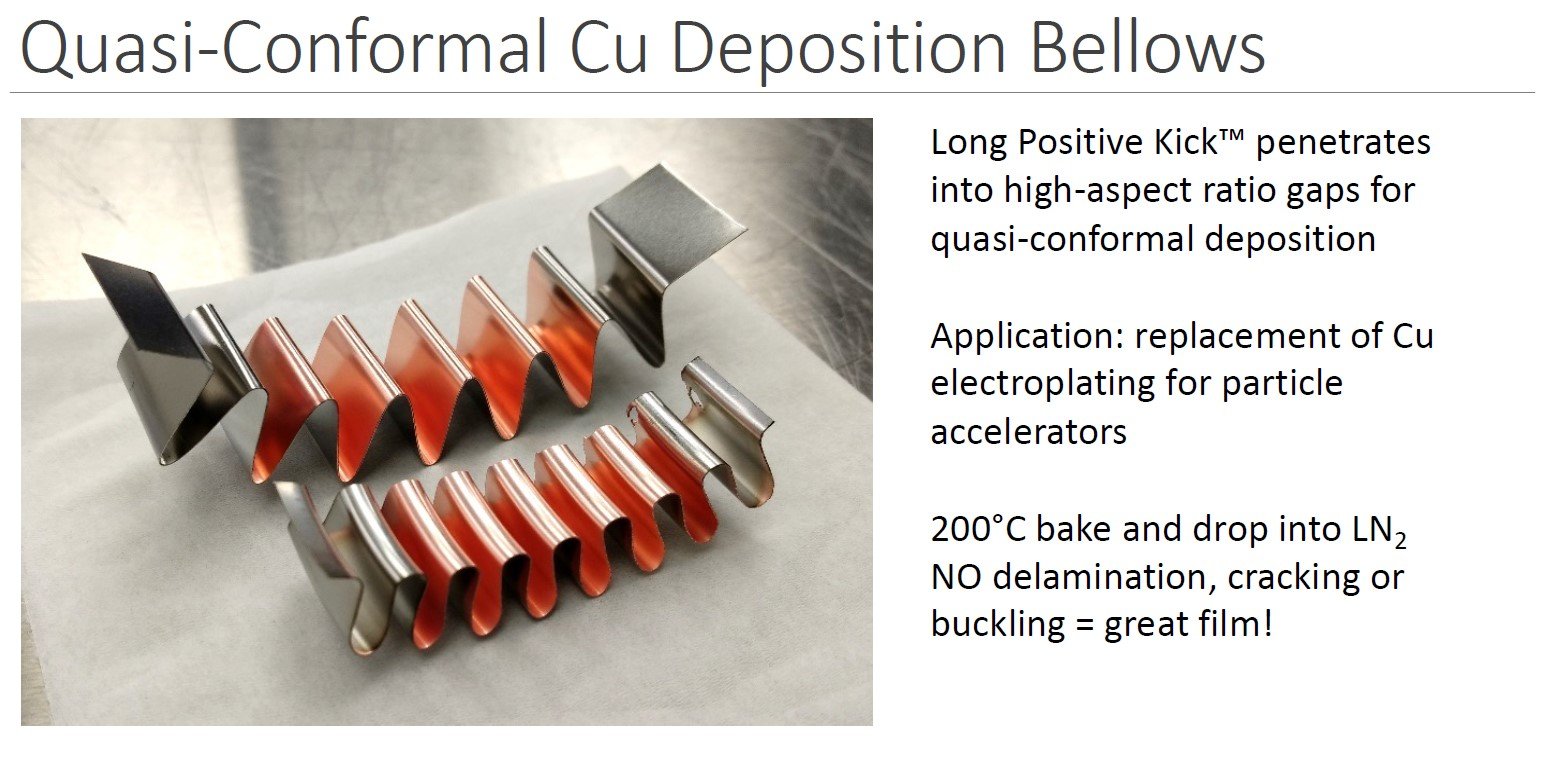

In order to control thin film coating morphology and conformality of coverage in magnetron sputtering processes, one has to have control over the nature and energy of the arriving coating material and gas species. HIPIMS allows for such control by ionizing the sputtered target material and increasing the plasma density overall. The ion energies achievable with HIPIMS are much higher than those achievable through conventional power delivery techniques (DC, Pulsed DC, MFAC, RF). Applying a positive voltage pulse at the end of the negative sputtering pulse allows one to “energize” the ionized target material and accelerate it towards the substrates. This creates the possibility to conformally coat Three dimensional structures without bias on insulating substrates.

GP Plasma collaborates with Starfire Industries LLC and Nano4Energy SL for positive kick HiPIMS power supply technologies.

https://www.starfireindustries.com

https://nano4energy.eu/

Technology

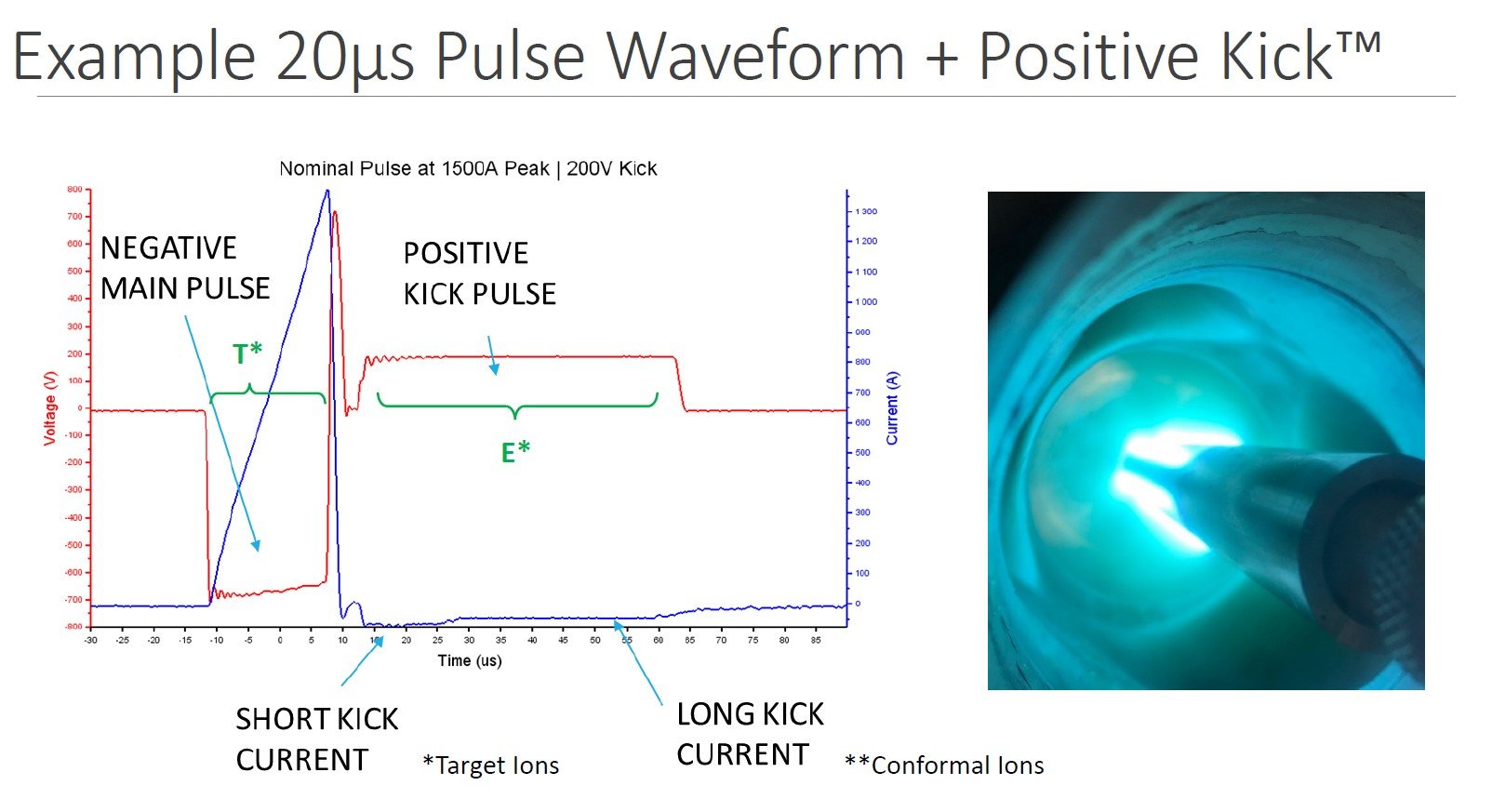

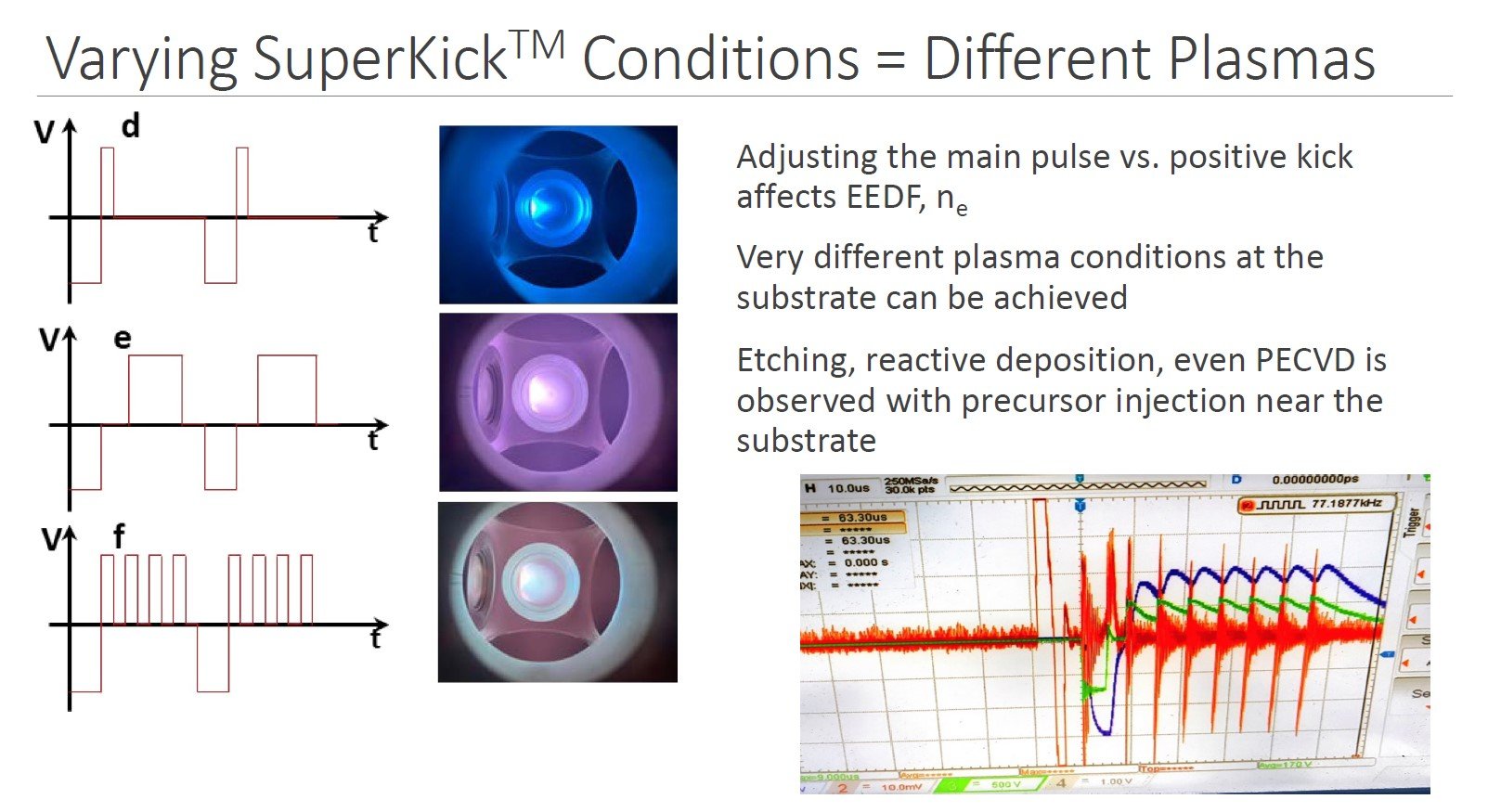

Changing the peak current, length of the pulse and synchronization with a bias supply, one can determine the degree of ionization of sputtered target material, ion energy and which ions are affected by the bias potential. The positive voltage reversal pulse adjacent to the negative sputtering pulse gives the ability to “accelerate” ions in front of the target towards the substrate with a determined energy.

HIPIMS offers the unique ability to have a “self” ion assisted sputtering process where one can control ion species and energies.

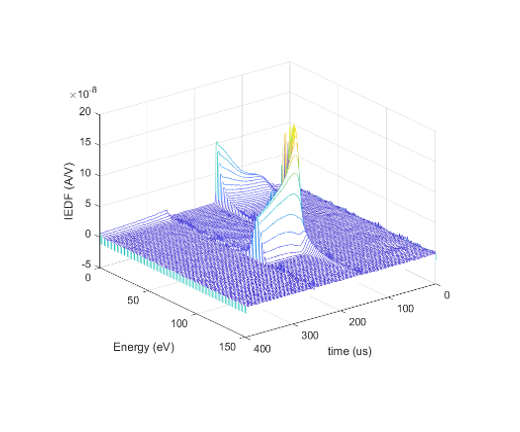

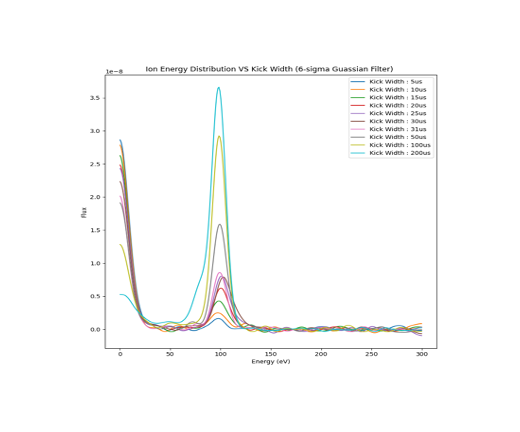

Ion Energy

Ion Energy Distribution Functions showing the effect of an applied positive reversal pulse at the end of the negative sputtering pulse. The graphs show the energies of ions can be significantly influenced by this positive reversal pulse.

This allows one to “tailor” coating properties as well as to deposit dense, well adhered coatings to non-conductive substrates at low temperatures.

Coating on Polymer Web

Depositing dense coatings on insulating substrates at low temperatures without a bias is a difficult task. In this example, a PET web has been coated with TiO2 using reactive deposition from Ti targets. In the case of pulsed DC, the columnar coating morphology and layers from multiple deposition passes are evident. With HIPIMS and a positive voltage reversal, the morphology becomes glassy and the delineation between layers disappears.

Work done in collaboration with Intellivation on their R2R-500 system.

Conformal Coatings on Insulating Substrates

Achieving conformal coatings with PVD on the side wall and bottom of trenches with PVD technology has always been a challenge. This challenge is further increased when the substrate is insulating, and no bias can be applied.

In this example, Al has been deposited at room temperature onto a patterned ceramic substrate. Conformal coating of all trench walls has been achieved by applying the proper HIPIMS power to the target.

Work done in collaboration with Malachite Technologies on an R&D tool.

Successful HIPIMS System Integration